Converting the Revell/Matchbox 1/72 Flower into an RCN Corvette:

Pt 3

Backdating to a Short Fo'c'sle

|

|

The moment of truth is at hand .. converting the Revell/Matchbox kit

from a late war, long fo'c'sle, hull, into an early war, short fo'c'sle,

corvette. The basic conversion is relatively easy and just requires the

desire to do it.

Hull prior to conversion |

I started by cutting the main deck at the new break. This was just behind

the rear of the gun platform, and happily fell at the two locators for

the dodger. I drew a line across the deck and then cut it out using a

new Exacto blade and a steel straight edge. I left a small piece in the

middle for later mounting of the mast.

With the deck cut I placed it on the hull and marked where the hull

should be cut. A template was made by tracing the outline of the kit fo'c'sle

break unto thick card. This was cut out and then used to draw a new outline

at the desired location. On my model this fell on one of the starboard

portholes. Don't worry about that as you can fill it in. Once the break

was drawn I extended the line along the hull to the aft section following

the line of the plating leaving a 3mm deep section that resembles the

kit cap strip along the top of the plating.

To

cut out the hull section I took a deep breath and used one of the rotary

cutting tools in my Dremel (not the Mini-Mite). I ran this at pretty well

the top speed and cut most of the material away, leaving a couple of millimeters

for cleanup. I then used the thicker of my two rotary saws and cut the

line as close as I dared. The final step was to use a rotary sanding drum

and smooth out the line and the fo'c'sle break. I left the overlapping

section of the hull relatively intact since it will be covered by the

boat deck when done. But I did thin the top of it so it isn't readily

apparent that it is thicker than the surrounding sections. All in all

this was an hour of work from start to finish. To

cut out the hull section I took a deep breath and used one of the rotary

cutting tools in my Dremel (not the Mini-Mite). I ran this at pretty well

the top speed and cut most of the material away, leaving a couple of millimeters

for cleanup. I then used the thicker of my two rotary saws and cut the

line as close as I dared. The final step was to use a rotary sanding drum

and smooth out the line and the fo'c'sle break. I left the overlapping

section of the hull relatively intact since it will be covered by the

boat deck when done. But I did thin the top of it so it isn't readily

apparent that it is thicker than the surrounding sections. All in all

this was an hour of work from start to finish.

Next up was a new deck for the hull. The first step is to determine

where the new deck will sit inside the hull. The aft deck is 16mm below

the level of the gunwale, so I marked off this distance down the hull

and then glued athwartship braces 2mm below these marks. Finally, other

pieces of .040 stock were glued to the sides to support the new deck.

I had intended to use the rest of the kit deck to construct the new deck,

but that would mean an extension would be required where it goes under

the fo'c'sle. Therefore I used .060 Evergreen sheet to do this in one

piece. The deck was traced unto a piece of card and this was cut out.

I then repeatedly cut away sections until it fit in place.

The

area under the fo'c'sle was what I had been waiting to build ever since

I decided to do a short fo'c'sle Flower. I had always thought that this

was a straight section from side to side. Not so, in fact it is more like

a 'W' in that it angles inwards on each side and has a small hut at the

extreme end of it in the middle. I began this by marking off the centre

of the gun platform on the top of the hull. This line was then extended

down unto the deck to provide the forward end of the enclosed space. The

bow has a pronounced camber to it, therefore I would have to make the

top of the bulkhead slightly curved. To do this I placed the edge of the

remaining deck section on a piece of .040 card and traced the curve. This

was then cut out and placed on the deck and the bow section was test fitted

over top of it. To enable the bulkhead to stand upright I added a support

to it outside of the exposed area. The bottom was repeatedly cut away

until the bow sat flush on top of the bulkhead. The

area under the fo'c'sle was what I had been waiting to build ever since

I decided to do a short fo'c'sle Flower. I had always thought that this

was a straight section from side to side. Not so, in fact it is more like

a 'W' in that it angles inwards on each side and has a small hut at the

extreme end of it in the middle. I began this by marking off the centre

of the gun platform on the top of the hull. This line was then extended

down unto the deck to provide the forward end of the enclosed space. The

bow has a pronounced camber to it, therefore I would have to make the

top of the bulkhead slightly curved. To do this I placed the edge of the

remaining deck section on a piece of .040 card and traced the curve. This

was then cut out and placed on the deck and the bow section was test fitted

over top of it. To enable the bulkhead to stand upright I added a support

to it outside of the exposed area. The bottom was repeatedly cut away

until the bow sat flush on top of the bulkhead.

The two side pieces were cut to fit and after similar test fittings

were glued in place. The small compartment at the front followed. Finally

the two exposed bulkheads were added. These took awhile to get the curvature

of the sides to match the hull. Portholes were drilled and they were then

affixed in place.

Doors for the various compartments under the fo'c'sle are still needed,

same with internal access if a radio-controlled model is desired, but

the basic hull conversion is now complete.

Superstructure

I

was worried about the superstructure and had no plan of how I would proceed,

instead I just jumped in and decided I would make it up as I went along.

This method worked out pretty well, except I made two major wrong turns

that ended up taking two evenings to correct. I

was worried about the superstructure and had no plan of how I would proceed,

instead I just jumped in and decided I would make it up as I went along.

This method worked out pretty well, except I made two major wrong turns

that ended up taking two evenings to correct.

I began by extending the engine room casing forward to the front of

the galley. To do this I placed the casing on the hull and held a piece

of .040 styrene sheet against it and traced the resulting angle unto it.

The upper edge of the casing was also marked. This line was then extended

forward 81mm on the top. A vertical line was then drawn unto it for the

rear edge of the galley keeping the angle constant (this was my first

mistake, I should have done it perpendicular to the upper edge). Another

27mm was added to the horizontal section and then a 98mm line was drawn

on the bottom. This gave the sides to the casing as far forward as the

front of the galley. These were cut out and joined to the original casing

with a section of scrap covering the back of the joins. RN Flowers did

not have this galley, so just extend the top and bottom lines forward

98mm.

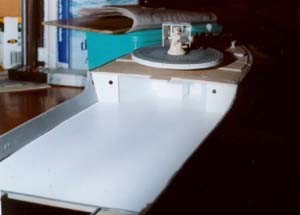

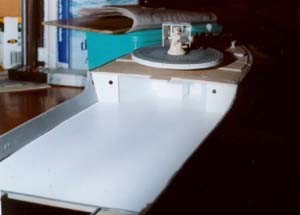

The

galley was covered with a 68mm x 27mm piece of sheet styrene and I then

turned to the remainder of the casing/boat deck. On RCN Flowers the boat

deck is alongside of the funnel, on RN Flowers it is forward, so decide

which variant you are building before cutting the plastic. I did this

deck in one piece so that it sits on top of the new sides and alongside

the existing casing. Overall it is 139mm long, with the boat deck starting

at 38mm from the front, and a 39mm x 68mm cutout for the original casing

at the rear. The

galley was covered with a 68mm x 27mm piece of sheet styrene and I then

turned to the remainder of the casing/boat deck. On RCN Flowers the boat

deck is alongside of the funnel, on RN Flowers it is forward, so decide

which variant you are building before cutting the plastic. I did this

deck in one piece so that it sits on top of the new sides and alongside

the existing casing. Overall it is 139mm long, with the boat deck starting

at 38mm from the front, and a 39mm x 68mm cutout for the original casing

at the rear.

Forward of the galley there is a sheltered alcove on either side with

doors leading to the interior. To make this alcove I glued narrow strip

to the front of the extended casing (next time I'll use one solid piece).

I then marked the lower bridge structure by repeating the trick of tracing

the edge of the casing unto card (40mm x75mm). Again I made a mistake

in keeping the angles perpendicular to the deck - we'll deal with this

later. The outside edge of the lower bridge extends to the front of the

galley, but does not touch it as the alcove on each side is behind it.

To make this alcove I traced the shape of the rear of the bridge sides

unto card and affixed this slightly in from the side of the galley. To

these pieces I then glued two pieces to bridge the gap between the bridge

side and the alcove sides.

The lower bridge was now ready for completion. The front was a piece

cut to 40mm x 90mm. A deck for this was made with 10mmx20mm extensions

for the ladders at the forward edge, and 5mm at the rear to overlap the

galley. All of these were then taped in place to see what it looked like.

It was then that I realized that I have made a mistake in following the

angle of the waterline as the wheelhouse and compass house were to be

square in all dimensions, but that would not give a straight line appearance

to the front edge. To fix this I cut the front of the lower bridge down

to 37mm, and also did the same to the front edge of each lower bridge

side. The upper levels would now sit with all front angles vertical. ..

however as can be seen in the photos the entire bridge/galley structure

now appears to angle down towards the bow .. I decided to leave it for

now and turned to the wheelhouse and charthouse.

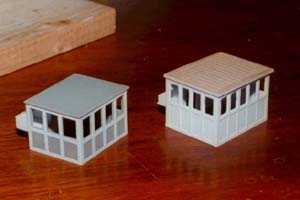

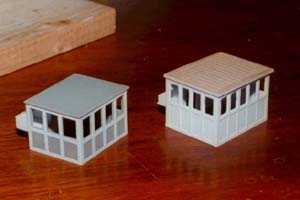

Modified kit wheelhouse as compass house |

The kit wheelhouse is more representational than accurate, but I decided

it could be modified into an acceptable compass house for the roof of

the wheelhouse. To do this I cut it at the level of the platform that

surrounds it, and also reduced the width/length to be four windows on

the front and three on the sides. A roof was added from the former rear

of the wheelhouse. The rear was cut from sheet styrene and glued in place.

The wheelhouse and compass house on the real thing were constructed

of wood, not metal, and as such are heavily framed. At first I wasn't

going to bother with this, but the compass house looked rather stark as

is, so I glued .080 x .010 strips around the top, bottom and sides of

the house (next time I'll use a wider strip on the bottom), and also in

between each window. Another strip was added between each vertical frame

1mm below each window. I now noticed that I hadn't paid attention to the

fact that the kit windows are slightly different widths and that they

also differ in spacing between them on the front and sides – and

I hadn't matched these differences when I set up the house. Therefore

I used the Exacto blade to extend the outside windows on each side to

1mm from the frame.

Wheelhouse prior to adding window framing |

The rear of the compass house requires a window, door and an alcove

for the charts to be added. First I added the four strips around the outside,

then verticals/horizontal for the window and door frames. The window and

door were cut out by making a few pilot holes with the Exacto blade as

a drill, these were then carefully cut out to be 1mm from the edge for

the window and flush with the frame for the door. The alcove was then

cut out and built from sheet styrene. Finally the door was built in a

similar fashion to the rest of the structure with frames around the outside

and below the window.

For the wheelhouse I cut four pieces of 32mm x 90mm out of .040 styrene.

Seven windows would be required on the front, and three on each side (plus

a door). After a few false starts I finally got these evenly spaced out

on the front by measuring 3mm in from each side and then going 5.5mm for

a window and 3mm for the gap. The .080 x .010 top and bottom and edge

strips were affixed, and as I was running out of this size stock I switched

to .060 x .010 for the verticals between the windows. I need not have

measured the windows, rather I just glued these at the centre mark for

each gap. Measuring down from the bottom of the top strip, I marked a

line 9mm down and added the horizontal strips at the bottom of the windows.

I then cut out each window as before using a new Exacto blade, this time

leaving a .5mm border. To this border I glued .020 square stock as a proper

frame

Scratchbuilt compass house with framing added around windows |

The sides were done in basically the same way, with the addition of

a door where the front window should go if the door was closed. I placed

the sides so that the front piece overlapped their leading edge, marked

off where the .080 cap strip would lie on the vertical to cover this join

and then where the verticals go for the door and window. The starboard

side was done first and I then traced out the location on this piece to

do the port side.

The port side differed in that I chose to make an alcove at the rear

of it for the ladder to the upper bridge section. This is shown on plans

as covered over with a wall or open, so I decided to use artistic license

and have it open.

Kit conversion and scratchbuilt compass houses |

Eight hours after starting, the upper levels of the bridge were done.

.. except the converted kit compass house looked wrong now .. the windows

are too big (and too few), it is a little too narrow and it is also too

short ...... The next day I rebuilt it as per the wheelhouse, but with

five windows on the front, four on the sides and two on the rear (plus

a door and the chart alcove). The final step to these is to construct

the roof to the compass house and deck between it and the wheelhouse.

These were cut from styrene and basswood decking was epoxied to them for

a real wood deck. This really adds to the overall look.

This brings us back to the lower bridge. I finally decided to fix this

by going back and redoing the extension to the casing, but with the verticals

perpendicular to the bottom of it. Therefore only the rearmost cut is

now to be angled, all others are right angles and dimensions adjusted

accordingly.

With

the exteriors done, I could now turn to the interior of the wheel and

charthouses. The same method of framing the outside was used on the interior

of each level and diagonal bracess added as well. In addition I also scratchbuilt

the interior furnishings for the two houses but that is for another time With

the exteriors done, I could now turn to the interior of the wheel and

charthouses. The same method of framing the outside was used on the interior

of each level and diagonal bracess added as well. In addition I also scratchbuilt

the interior furnishings for the two houses but that is for another time

|

To

cut out the hull section I took a deep breath and used one of the rotary

cutting tools in my Dremel (not the Mini-Mite). I ran this at pretty well

the top speed and cut most of the material away, leaving a couple of millimeters

for cleanup. I then used the thicker of my two rotary saws and cut the

line as close as I dared. The final step was to use a rotary sanding drum

and smooth out the line and the fo'c'sle break. I left the overlapping

section of the hull relatively intact since it will be covered by the

boat deck when done. But I did thin the top of it so it isn't readily

apparent that it is thicker than the surrounding sections. All in all

this was an hour of work from start to finish.

To

cut out the hull section I took a deep breath and used one of the rotary

cutting tools in my Dremel (not the Mini-Mite). I ran this at pretty well

the top speed and cut most of the material away, leaving a couple of millimeters

for cleanup. I then used the thicker of my two rotary saws and cut the

line as close as I dared. The final step was to use a rotary sanding drum

and smooth out the line and the fo'c'sle break. I left the overlapping

section of the hull relatively intact since it will be covered by the

boat deck when done. But I did thin the top of it so it isn't readily

apparent that it is thicker than the surrounding sections. All in all

this was an hour of work from start to finish.  The

area under the fo'c'sle was what I had been waiting to build ever since

I decided to do a short fo'c'sle Flower. I had always thought that this

was a straight section from side to side. Not so, in fact it is more like

a 'W' in that it angles inwards on each side and has a small hut at the

extreme end of it in the middle. I began this by marking off the centre

of the gun platform on the top of the hull. This line was then extended

down unto the deck to provide the forward end of the enclosed space. The

bow has a pronounced camber to it, therefore I would have to make the

top of the bulkhead slightly curved. To do this I placed the edge of the

remaining deck section on a piece of .040 card and traced the curve. This

was then cut out and placed on the deck and the bow section was test fitted

over top of it. To enable the bulkhead to stand upright I added a support

to it outside of the exposed area. The bottom was repeatedly cut away

until the bow sat flush on top of the bulkhead.

The

area under the fo'c'sle was what I had been waiting to build ever since

I decided to do a short fo'c'sle Flower. I had always thought that this

was a straight section from side to side. Not so, in fact it is more like

a 'W' in that it angles inwards on each side and has a small hut at the

extreme end of it in the middle. I began this by marking off the centre

of the gun platform on the top of the hull. This line was then extended

down unto the deck to provide the forward end of the enclosed space. The

bow has a pronounced camber to it, therefore I would have to make the

top of the bulkhead slightly curved. To do this I placed the edge of the

remaining deck section on a piece of .040 card and traced the curve. This

was then cut out and placed on the deck and the bow section was test fitted

over top of it. To enable the bulkhead to stand upright I added a support

to it outside of the exposed area. The bottom was repeatedly cut away

until the bow sat flush on top of the bulkhead.  I

was worried about the superstructure and had no plan of how I would proceed,

instead I just jumped in and decided I would make it up as I went along.

This method worked out pretty well, except I made two major wrong turns

that ended up taking two evenings to correct.

I

was worried about the superstructure and had no plan of how I would proceed,

instead I just jumped in and decided I would make it up as I went along.

This method worked out pretty well, except I made two major wrong turns

that ended up taking two evenings to correct.  The

galley was covered with a 68mm x 27mm piece of sheet styrene and I then

turned to the remainder of the casing/boat deck. On RCN Flowers the boat

deck is alongside of the funnel, on RN Flowers it is forward, so decide

which variant you are building before cutting the plastic. I did this

deck in one piece so that it sits on top of the new sides and alongside

the existing casing. Overall it is 139mm long, with the boat deck starting

at 38mm from the front, and a 39mm x 68mm cutout for the original casing

at the rear.

The

galley was covered with a 68mm x 27mm piece of sheet styrene and I then

turned to the remainder of the casing/boat deck. On RCN Flowers the boat

deck is alongside of the funnel, on RN Flowers it is forward, so decide

which variant you are building before cutting the plastic. I did this

deck in one piece so that it sits on top of the new sides and alongside

the existing casing. Overall it is 139mm long, with the boat deck starting

at 38mm from the front, and a 39mm x 68mm cutout for the original casing

at the rear.