Accurizing the Matchbox/Revell 1/72 Flower Class Corvette Pt.7

Funnel & Vents

|

|

One of the things that struck me as needing more detail was the kit

funnel and vents. The funnel is a very basic representation of the real

thing and can stand to have some easy additions made to improve its

appearance. One thing that is noticably lacking are rivets to the funnel.

There should be six vertical and four horizontal rows of rivets. Great

Little Ships offers a brass overlay that has this detail in place,

and for those so inclined I can't recommend their products enough ..

however I am trying to scratchbuild as much of this model as possible

and I decided to try my hand at making my own overlay.

A

friend of mine sent me a tracing of his GLS funnel overlay and I then

traced this onto a new sheet and saved the original for future models.

The tracing was taped to a piece of .005" evergreen styrene and

using one of those wheel tracing thingies from the sewing shop, I ran

it along a steel ruler to emboss the rivet pattern on the reverse side.

Be sure to place the styrene on top of a surface with some give so as

to allow the rivets to form. This should not be so soft that the styrene

distorts however. A

friend of mine sent me a tracing of his GLS funnel overlay and I then

traced this onto a new sheet and saved the original for future models.

The tracing was taped to a piece of .005" evergreen styrene and

using one of those wheel tracing thingies from the sewing shop, I ran

it along a steel ruler to emboss the rivet pattern on the reverse side.

Be sure to place the styrene on top of a surface with some give so as

to allow the rivets to form. This should not be so soft that the styrene

distorts however.

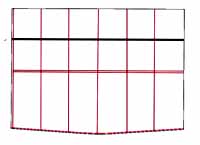

Note

that the horizontal rivets are arranged in three groupings. .. the one

on top is actually on a separate piece of styrene and is done later.

The next set down has a double band close together, while at the very

bottom is the final row. On the drawing, the rivet lines are shown in

red, while the reinforcing band with the additional strip is shown as

a wider black line. For those making use of this template, the full

size image should be set to print at 150dpi, otherwise you shall have

a 1/32 scale funnel!! Note

that the horizontal rivets are arranged in three groupings. .. the one

on top is actually on a separate piece of styrene and is done later.

The next set down has a double band close together, while at the very

bottom is the final row. On the drawing, the rivet lines are shown in

red, while the reinforcing band with the additional strip is shown as

a wider black line. For those making use of this template, the full

size image should be set to print at 150dpi, otherwise you shall have

a 1/32 scale funnel!!

The

raised band on the kit funnel should be removed. I used a sanding drum

on my Dremel and followed that up with some light hand sanding. Cut

the overlay slightly oversize on one edge and along the top, and check

for fit to the funnel. .. trim the side to ensure a snug fit. I then

coated the funnel with Testors Liquid cement and wrapped the overlay

around the funnel, making sure that the join is held together. When

dry, trim the excess from the top. The

raised band on the kit funnel should be removed. I used a sanding drum

on my Dremel and followed that up with some light hand sanding. Cut

the overlay slightly oversize on one edge and along the top, and check

for fit to the funnel. .. trim the side to ensure a snug fit. I then

coated the funnel with Testors Liquid cement and wrapped the overlay

around the funnel, making sure that the join is held together. When

dry, trim the excess from the top.

The

reinforcing band around the top is now added. this was a strip of .080

x .020 that was also embossed with a rivet pattern. Once this was in

place the attachment points for the rigging was begun. I used .017 brass

rod to make the loops and also to make the holes in which they fit to

the funnel. A section of the wire was placed in my pinvise and used

to drill a hole along the reinforcing band. The brass loop was then

placed into the hole and the location of the second hole was marked

above the first .. this was drilled and the rung was then CAed in place.

There are four of these arranged in an X pattern when viewed from above. The

reinforcing band around the top is now added. this was a strip of .080

x .020 that was also embossed with a rivet pattern. Once this was in

place the attachment points for the rigging was begun. I used .017 brass

rod to make the loops and also to make the holes in which they fit to

the funnel. A section of the wire was placed in my pinvise and used

to drill a hole along the reinforcing band. The brass loop was then

placed into the hole and the location of the second hole was marked

above the first .. this was drilled and the rung was then CAed in place.

There are four of these arranged in an X pattern when viewed from above.

The

screen atop the funnel should also be replaced with a better one, however

for now I have just raised its height to allow a gap between it and

the funnel by gluing a ring of styrene about 2mm below the inside lip

of the funnel - the cap sits on this lip and is thus raised from the

funnel. The

screen atop the funnel should also be replaced with a better one, however

for now I have just raised its height to allow a gap between it and

the funnel by gluing a ring of styrene about 2mm below the inside lip

of the funnel - the cap sits on this lip and is thus raised from the

funnel.

The funnel was later sprayed with a grey primer and a month or two

later with WEM's Colourcoat RN White, followed by Colourcoat WA Blue.

The next step was to add the red/white barberpole marking of Escort

Group C-3. This was done on my Alps printer and went on quite nicely.

The final step was to add the green RCN Maple Leaf – also a product

of the Alps.

VENTS

As

mentioned in the basic

accurizing article, the vents can be improved by thinning down the

section of the mouth on them. However something still seemed wrong.

A look at various photos showed that the real vents were designed to

be able to be turned into (or out of) prevailing winds and other assorted

weather. In order to accomplish this, the four tall vents beside the

funnel have an arrangement of rollers and shafts that allow the top

portion to be turned from below. As

mentioned in the basic

accurizing article, the vents can be improved by thinning down the

section of the mouth on them. However something still seemed wrong.

A look at various photos showed that the real vents were designed to

be able to be turned into (or out of) prevailing winds and other assorted

weather. In order to accomplish this, the four tall vents beside the

funnel have an arrangement of rollers and shafts that allow the top

portion to be turned from below.

I

began by removing the raised bands on the vents and replacing them with

strip styrene. There is a .015 x .060 strip along the bottom, and a

.010 x .120 for the wider band at the top. This then has a .015 x.060

strip added for the gearing. The gear itself is embossed aluminum foil.

The rollers are the Slaters rod included with the kit, while the rotating

gear is .017 brass rod with the Slaters rod on the end. This fits into

a hole on the funnel deck. The final touch is the removable panel on

each of the four large vents. I

began by removing the raised bands on the vents and replacing them with

strip styrene. There is a .015 x .060 strip along the bottom, and a

.010 x .120 for the wider band at the top. This then has a .015 x.060

strip added for the gearing. The gear itself is embossed aluminum foil.

The rollers are the Slaters rod included with the kit, while the rotating

gear is .017 brass rod with the Slaters rod on the end. This fits into

a hole on the funnel deck. The final touch is the removable panel on

each of the four large vents.

If I was to do these again, I would use thinner styrene, as they still

appear to be slighty overscale .. but they are far better than the kit

parts.

I would like to thank David Parkins of GLS

for allowing me to make use of the tracing of his funnel overlay in

this article.

|