Converting the Revell Flower Class Corvette kit to an early

RCN Short Fo'c'sle Flower: HMCS Agassiz

|

|

Introduction

This is a conversion that I have wanted to do for some time but have

not had the courage up until now to have a go. The major reference is

the book "Anatomy of the Ship

HMCS Agassiz" by John McKay & John Harland this gives all the details

required of the actual ship and her equipment. I also used the following

books "Canada's Flowers"

by Thomas G Lynch, and "Corvettes

of the Royal Canadian Navy" by Ken Macpherson for further information,

and of course the book Warship Perspective, "Flower"

Class Corvettes in World War 2 by John Lambert

This

conversion entails shortening the forecastle of the kit, squaring off

the stern to the Canadian type, remodelling the bow by the removal of

the bow strake & prominent keel moulded by Revell. Repositioning the

ships boats and some of the armament. To put it simply a major rebuild

and severe kit bashing exercise This

conversion entails shortening the forecastle of the kit, squaring off

the stern to the Canadian type, remodelling the bow by the removal of

the bow strake & prominent keel moulded by Revell. Repositioning the

ships boats and some of the armament. To put it simply a major rebuild

and severe kit bashing exercise

For the actual conversion I used Bob

Pearson's templates. These templates give all details needed for

the conversion including new short fo'c'sle, new decks, superstructure

and bridge details. All that is required is the time and inclination

to get on with the conversion. Included in the package are pennant numbers

and gun shield art for other Canadian "Flower" class Corvettes.

The Conversion Starts

The stern is squared off by heating the material, I used a hair dryer

but any source of heat will do the job and reshaping the stern. This

will cause the hull to be about 1/2" short of the scale length. To bring

it back to the proper length, plates are cut from plastic card and the

gap between the two halves filled.

At the stern, new decks have to be made to fit the altered hull shape.

Cut out the apertures for the depth charge chutes and the minesweeping

fairleads. Deck surfaces have to be sanded down to remove the incorrect

Revel moulded planking and also various other deck markings have to

be removed which are now redundant. A new bridge and superstructure

built to the to the Canadian style, building the early commercial type

"A" bridge structure.

The hull is then turned upside down on the bench and the prominent

keel which Revell have moulded in which runs from the bow to the propeller

has to be removed, [look at the drawings on pages 36/37 & 41 of the

Anatomy of the ship HMCS Agassiz and it will be seen that no such keel

is shown]. This can be done in two ways either before the hull halves

are put together or afterwards, I prefer the latter as I think that

it makes for a more secure joint in the hull.

To do the actual removal I used my Dremel mini drill with the sanding

attachment and after a lot of work the result was that the prominent

keel had been removed, any small imperfections that are found can be

filled with body filler [I use P38 car filler] this is then sanded down

to obtain a smooth finish to the lower hull.

The hull joint can be reinforced on the inside of the hull to ensure

that the joint that you have sanded down from the outside is not weakened

in any way. For this I use Fibre Glass Resin but if you use this remember

that resin as it cures generates heat and must be cooled as it cures

to prevent any possibility of the hull distorting, I found the simplest

way of doing this is to place the hull in cold water while the resin

is curing. Once you are satisfied with the finish it is then time to

add the bilge keels to both sides of the hull at the positions indicated

in the kit. There will be small gap of about 1/2" in the middle that

requires building up here due to the hull sections being moved forward.

Once

the two halves of the hull are put together I then installed the motor

mount, which consists of a plastic card plate 4mm thick cut to size

and the centre line marked to allow for the gear drive. This is then

cut out and the motor fitted. The motor is then screwed down and the

alignment rechecked and the when satisfied the complete assembly is

stuck into place. Once

the two halves of the hull are put together I then installed the motor

mount, which consists of a plastic card plate 4mm thick cut to size

and the centre line marked to allow for the gear drive. This is then

cut out and the motor fitted. The motor is then screwed down and the

alignment rechecked and the when satisfied the complete assembly is

stuck into place.

For the rudder I used the kit rudder with a small commercial rudder

sandwiched between the plastic blades to give it the required strength

and at the same time provide the necessary rudder arm.

Now

turn the hull back to the correct position and from the templates, cut

the lower guide for the removal of the excess hull to reshape the actual

hull for the short forecastle. For this I used mini drill and saw blade

attachment. When this is done the overlap of the fore and aft hull sections

must be carefully removed from inside the hull as this will show on

the bulwarks of the finished hull, again I used the mini drill but this

time with a sanding disc in place. A check was done on the drawings

in AOS against the hull of the kit and it was found that scuttles as

drilled in the kit were incorrect for the short fo'c'sle version so

new scuttles and eyebrows have to be drilled and marked in the proper

positions. Now

turn the hull back to the correct position and from the templates, cut

the lower guide for the removal of the excess hull to reshape the actual

hull for the short forecastle. For this I used mini drill and saw blade

attachment. When this is done the overlap of the fore and aft hull sections

must be carefully removed from inside the hull as this will show on

the bulwarks of the finished hull, again I used the mini drill but this

time with a sanding disc in place. A check was done on the drawings

in AOS against the hull of the kit and it was found that scuttles as

drilled in the kit were incorrect for the short fo'c'sle version so

new scuttles and eyebrows have to be drilled and marked in the proper

positions.

When

this is complete it is time to turn to the decks. As was said earlier

Revel have planked all the decking and this has to be removed. I started

on the fore deck and after cutting the shortened fore deck to the length

required for the short forecastle, this was sanded down to remove all

the markings on the fore deck. A new main deck was cut from plastic

card using the kit deck and templates for the shape and length. This

avoids several joins in the decking if the kit deck is used and also

cuts out all the sanding required to remove Revell's marks. Scribing

the lines on the decking with a craft knife marks the deck plating on.

Inside the hull a line was drawn about 7/10ths down from the bulwarks

this is for a datum line for the main deck. A supporting strip was stuck

inside the hull along this line for the deck to sit on. When

this is complete it is time to turn to the decks. As was said earlier

Revel have planked all the decking and this has to be removed. I started

on the fore deck and after cutting the shortened fore deck to the length

required for the short forecastle, this was sanded down to remove all

the markings on the fore deck. A new main deck was cut from plastic

card using the kit deck and templates for the shape and length. This

avoids several joins in the decking if the kit deck is used and also

cuts out all the sanding required to remove Revell's marks. Scribing

the lines on the decking with a craft knife marks the deck plating on.

Inside the hull a line was drawn about 7/10ths down from the bulwarks

this is for a datum line for the main deck. A supporting strip was stuck

inside the hull along this line for the deck to sit on.

Measurements were taken from the AOS Agassiz for the new superstructure

and the distance from the stern marked on the new deck for the Canadian

type engine room casing and superstructure, double check the measurements

then when satisfied that they are correct cut out the opening in the

deck.

When

you are satisfied that the new main deck is correct it is time to think

about the new engine room casing and its construction. The conversion

set contains a template shows the alterations that are required to carry

out this part of the conversion. When

you are satisfied that the new main deck is correct it is time to think

about the new engine room casing and its construction. The conversion

set contains a template shows the alterations that are required to carry

out this part of the conversion.

When the engine room casing is complete it is then time to look at

templates 8 & 9 both of which show the construction of the new forward

superstructure required for this type of ship. Note that these Templates

also cover the RN short forecastle version The kit funnel deck is used

with the front part G7 in the kit being replaced by a scratch made part

which goes right to the deck level

A

new engine room skylight is required as the one provided by Revel is

too high and too short plus there are insufficient number of skylights,

five each side against four as moulded by Revell. The new skylight should

measure 60mm by 7mm and 10mm high. This is then placed in position 66mm

from the aft end of the engine room casing. Hinges and handles are added

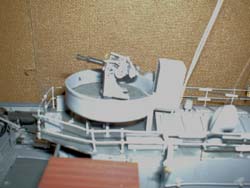

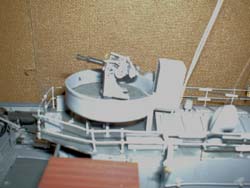

from strip plastic. The moulded on cone for the support of the 2pdr

has got to be removed from the kit position and the resulting hole filled

and repositioned where shown on template 7. A

new engine room skylight is required as the one provided by Revel is

too high and too short plus there are insufficient number of skylights,

five each side against four as moulded by Revell. The new skylight should

measure 60mm by 7mm and 10mm high. This is then placed in position 66mm

from the aft end of the engine room casing. Hinges and handles are added

from strip plastic. The moulded on cone for the support of the 2pdr

has got to be removed from the kit position and the resulting hole filled

and repositioned where shown on template 7.

The construction of the new wheelhouse is now started using Template

11. Since both the wheelhouse and compass house are of timber construction

I used scribed plastic card sheet to simulate the planking, strip plastic

and angle to make up the framework round the timber of the structure.

The

internal framework is put in place, as is a strip of plastic to support

the windows in position. The complete interior of the wheelhouse is

then painted teak colour to represent the wood construction of the structure.

Various internal details are such as wheel, telegraph and crew the radio

room details are added from scrap material to simulate radio etc. These

are shown on the template. The

internal framework is put in place, as is a strip of plastic to support

the windows in position. The complete interior of the wheelhouse is

then painted teak colour to represent the wood construction of the structure.

Various internal details are such as wheel, telegraph and crew the radio

room details are added from scrap material to simulate radio etc. These

are shown on the template.

Template 12 shows the dimensions required for the Compass House and

the decking over the wheelhouse and compass house roof. The planked

decks are again scribed plastic sheet. Also shown are the drawings for

the corrected RCN long fo'c'sle bridge, which also covers the later

type, fitted to the short fo'c'sle "Flower" class corvettes.

HMCS

Agassiz has the life rafts carried behind the bridge and at the same

level as the galley top and out the same width as the lifeboat deck

this shows the differences between ships. The templates show for other

early Flower class corvettes. The life raft platforms are made again

from plank scribed plastic and put into position. Before the complete

superstructure is fitted to the deck [for a sailing model] I put a raised

section of plastic of 1" all around the position that the superstructure

will sit on the deck, this does two jobs, HMCS

Agassiz has the life rafts carried behind the bridge and at the same

level as the galley top and out the same width as the lifeboat deck

this shows the differences between ships. The templates show for other

early Flower class corvettes. The life raft platforms are made again

from plank scribed plastic and put into position. Before the complete

superstructure is fitted to the deck [for a sailing model] I put a raised

section of plastic of 1" all around the position that the superstructure

will sit on the deck, this does two jobs,

[a] holds the super-structure in place and

[b] makes for a watertight joint between the deck and the superstructure.

I

used a combination of fittings from the kit purchased fittings from

Sirmar and scratch builds others. Replacement fittings are available

from Sirmar & APS models. If you want to go all out, you can buy the

etched brass fittings from Great Little Ships . However I found that

they were rather expensive but the final choice is up to the builder. I

used a combination of fittings from the kit purchased fittings from

Sirmar and scratch builds others. Replacement fittings are available

from Sirmar & APS models. If you want to go all out, you can buy the

etched brass fittings from Great Little Ships . However I found that

they were rather expensive but the final choice is up to the builder.

For a sailing model I believe that the normal fittings are good enough

if cleaned up and more detail added. If, however, you want a display

model then etched brass is the way to go.

The

various vents, hatches and skylights are now put in place on the superstructure.

The internal details in the compass house are taken from the AOS and

built and put in place. The glazing for the windows is now done and

the complete structure put in place. The

various vents, hatches and skylights are now put in place on the superstructure.

The internal details in the compass house are taken from the AOS and

built and put in place. The glazing for the windows is now done and

the complete structure put in place.

The supports for the life- boat decks and life raft decks are made

from [I beam, Evergreen 274] and are put in place. The supports for

the 2pdr platform made from [Evergreen angle 291] are cut and put in

place. The various lockers required are made from either adapting the

kit fittings or by scratch building and taking the dimensions from AOS.

The 4" gun shield is remade from thin plastic card [the original is

too thick] and the rivet lines on the plates scribed on. Internal braces

are put in place [using John Lambert's drawings for position] from Evergreen

angle 291.

The

next major part of the conversion is the construction of the actual

minesweeping winch, which

is a major fitting on the quarterdeck of these ships. The drawings in

the AOS are to 1/48th and have to be reduced to 1/72nd and all the measurements

are transferred to plastic card ready for cutting out and assembling.

If like me your maths are not very good [old age] that is my excuse

then the templates can be obtained from Bob Pearson. The

next major part of the conversion is the construction of the actual

minesweeping winch, which

is a major fitting on the quarterdeck of these ships. The drawings in

the AOS are to 1/48th and have to be reduced to 1/72nd and all the measurements

are transferred to plastic card ready for cutting out and assembling.

If like me your maths are not very good [old age] that is my excuse

then the templates can be obtained from Bob Pearson.

The foremast is situated in a false deck attached to the superstructure

to enable this to be detached without removing all the rigging from

the foremast to the deck. The false deck edge is feathered to conceal

the edge as much as possible and then it is painted as the proper deck

and marked for the plates, attached under the forward edge of the superstructure

the forward edge being in line with the break in the foícastle again

this helps to conceal the false deck edge as much as possible.

The foremast is then placed in position and glued down. The actual

rigging of the model will be left until the last thing as it will be

very simple to knock while fitting other details to the decking and

superstructure.

The dimensions for the paravanes are again reduced down from those

in AOS and constructed from plastic rod and tube then shaped and detailed.

Deck

stanchions [two packs are required from Sirmar] are added. Drill the

holes for the deck stanchions before adding the various items on the

superstructure; this makes things a lot less complicated. The deck rails

themselves being made from thin brass wire threaded through each of

the stanchions and the canvas dodger round the upper bridge is simulated

by using single sheet toilet paper and then sprayed grey to match the

hull colour and stuck into place. This when finished looks very much

like canvas and can be used for other details that require a canvas

look on the model such as lifeboat covers if you are fitting them. Deck

stanchions [two packs are required from Sirmar] are added. Drill the

holes for the deck stanchions before adding the various items on the

superstructure; this makes things a lot less complicated. The deck rails

themselves being made from thin brass wire threaded through each of

the stanchions and the canvas dodger round the upper bridge is simulated

by using single sheet toilet paper and then sprayed grey to match the

hull colour and stuck into place. This when finished looks very much

like canvas and can be used for other details that require a canvas

look on the model such as lifeboat covers if you are fitting them.

Minesweeping gallows are made and put in position, as are the otter

boards. Rigging is done and we have a new model based on the Revell

Flower class

|

This

conversion entails shortening the forecastle of the kit, squaring off

the stern to the Canadian type, remodelling the bow by the removal of

the bow strake & prominent keel moulded by Revell. Repositioning the

ships boats and some of the armament. To put it simply a major rebuild

and severe kit bashing exercise

This

conversion entails shortening the forecastle of the kit, squaring off

the stern to the Canadian type, remodelling the bow by the removal of

the bow strake & prominent keel moulded by Revell. Repositioning the

ships boats and some of the armament. To put it simply a major rebuild

and severe kit bashing exercise Once

the two halves of the hull are put together I then installed the motor

mount, which consists of a plastic card plate 4mm thick cut to size

and the centre line marked to allow for the gear drive. This is then

cut out and the motor fitted. The motor is then screwed down and the

alignment rechecked and the when satisfied the complete assembly is

stuck into place.

Once

the two halves of the hull are put together I then installed the motor

mount, which consists of a plastic card plate 4mm thick cut to size

and the centre line marked to allow for the gear drive. This is then

cut out and the motor fitted. The motor is then screwed down and the

alignment rechecked and the when satisfied the complete assembly is

stuck into place. Now

turn the hull back to the correct position and from the templates, cut

the lower guide for the removal of the excess hull to reshape the actual

hull for the short forecastle. For this I used mini drill and saw blade

attachment. When this is done the overlap of the fore and aft hull sections

must be carefully removed from inside the hull as this will show on

the bulwarks of the finished hull, again I used the mini drill but this

time with a sanding disc in place. A check was done on the drawings

in AOS against the hull of the kit and it was found that scuttles as

drilled in the kit were incorrect for the short fo'c'sle version so

new scuttles and eyebrows have to be drilled and marked in the proper

positions.

Now

turn the hull back to the correct position and from the templates, cut

the lower guide for the removal of the excess hull to reshape the actual

hull for the short forecastle. For this I used mini drill and saw blade

attachment. When this is done the overlap of the fore and aft hull sections

must be carefully removed from inside the hull as this will show on

the bulwarks of the finished hull, again I used the mini drill but this

time with a sanding disc in place. A check was done on the drawings

in AOS against the hull of the kit and it was found that scuttles as

drilled in the kit were incorrect for the short fo'c'sle version so

new scuttles and eyebrows have to be drilled and marked in the proper

positions.  When

this is complete it is time to turn to the decks. As was said earlier

Revel have planked all the decking and this has to be removed. I started

on the fore deck and after cutting the shortened fore deck to the length

required for the short forecastle, this was sanded down to remove all

the markings on the fore deck. A new main deck was cut from plastic

card using the kit deck and templates for the shape and length. This

avoids several joins in the decking if the kit deck is used and also

cuts out all the sanding required to remove Revell's marks. Scribing

the lines on the decking with a craft knife marks the deck plating on.

Inside the hull a line was drawn about 7/10ths down from the bulwarks

this is for a datum line for the main deck. A supporting strip was stuck

inside the hull along this line for the deck to sit on.

When

this is complete it is time to turn to the decks. As was said earlier

Revel have planked all the decking and this has to be removed. I started

on the fore deck and after cutting the shortened fore deck to the length

required for the short forecastle, this was sanded down to remove all

the markings on the fore deck. A new main deck was cut from plastic

card using the kit deck and templates for the shape and length. This

avoids several joins in the decking if the kit deck is used and also

cuts out all the sanding required to remove Revell's marks. Scribing

the lines on the decking with a craft knife marks the deck plating on.

Inside the hull a line was drawn about 7/10ths down from the bulwarks

this is for a datum line for the main deck. A supporting strip was stuck

inside the hull along this line for the deck to sit on. When

you are satisfied that the new main deck is correct it is time to think

about the new engine room casing and its construction. The conversion

set contains a template shows the alterations that are required to carry

out this part of the conversion.

When

you are satisfied that the new main deck is correct it is time to think

about the new engine room casing and its construction. The conversion

set contains a template shows the alterations that are required to carry

out this part of the conversion. A

new engine room skylight is required as the one provided by Revel is

too high and too short plus there are insufficient number of skylights,

five each side against four as moulded by Revell. The new skylight should

measure 60mm by 7mm and 10mm high. This is then placed in position 66mm

from the aft end of the engine room casing. Hinges and handles are added

from strip plastic. The moulded on cone for the support of the 2pdr

has got to be removed from the kit position and the resulting hole filled

and repositioned where shown on template 7.

A

new engine room skylight is required as the one provided by Revel is

too high and too short plus there are insufficient number of skylights,

five each side against four as moulded by Revell. The new skylight should

measure 60mm by 7mm and 10mm high. This is then placed in position 66mm

from the aft end of the engine room casing. Hinges and handles are added

from strip plastic. The moulded on cone for the support of the 2pdr

has got to be removed from the kit position and the resulting hole filled

and repositioned where shown on template 7. The

internal framework is put in place, as is a strip of plastic to support

the windows in position. The complete interior of the wheelhouse is

then painted teak colour to represent the wood construction of the structure.

Various internal details are such as wheel, telegraph and crew the radio

room details are added from scrap material to simulate radio etc. These

are shown on the template.

The

internal framework is put in place, as is a strip of plastic to support

the windows in position. The complete interior of the wheelhouse is

then painted teak colour to represent the wood construction of the structure.

Various internal details are such as wheel, telegraph and crew the radio

room details are added from scrap material to simulate radio etc. These

are shown on the template. HMCS

Agassiz has the life rafts carried behind the bridge and at the same

level as the galley top and out the same width as the lifeboat deck

this shows the differences between ships. The templates show for other

early Flower class corvettes. The life raft platforms are made again

from plank scribed plastic and put into position. Before the complete

superstructure is fitted to the deck [for a sailing model] I put a raised

section of plastic of 1" all around the position that the superstructure

will sit on the deck, this does two jobs,

HMCS

Agassiz has the life rafts carried behind the bridge and at the same

level as the galley top and out the same width as the lifeboat deck

this shows the differences between ships. The templates show for other

early Flower class corvettes. The life raft platforms are made again

from plank scribed plastic and put into position. Before the complete

superstructure is fitted to the deck [for a sailing model] I put a raised

section of plastic of 1" all around the position that the superstructure

will sit on the deck, this does two jobs,